Welcome to our website! Call us: +86-18622194621 E-mail: toptac@fancyco.com

Views: 0 Author: Site Editor Publish Time: 2025-11-04 Origin: Site

Lithium-ion batteries use thin-film membranes like PP and PE. These membranes help store energy in a safe way.

Here are some facts about the market:

The battery separators market may reach USD 13.0 billion by 2028.

PE separators are popular because of new batteries.

PP separators are growing fast at 9.37% each year from 2024 to 2031.

Separator Type | Melting Point (°C) | Role in Battery Safety |

|---|---|---|

Polypropylene (PP) | 165 | Keeps battery strong |

Polyethylene (PE) | 135 | Stops battery if too hot |

Think about what you need before you pick between PP and PE separators.

PP separators work well in hot places. They melt at 165°C. This makes them good for things that get very hot.

PE separators melt at 135°C. They shut down fast if it gets too hot. This helps keep batteries safe.

Picking the right separator changes how the battery works. It also affects safety and how long it lasts. Think about what your battery needs.

You can change PP and PE separators for different uses. This helps them fit many battery types.

You can recycle both PP and PE separators. This helps protect the environment.

Polypropylene separators are used in batteries. They help keep batteries safe and strong. Polypropylene is a plastic that does not melt easily. It also does not get damaged by chemicals. These separators are found in lithium-ion batteries and other devices. There are two main ways to make polypropylene separators.

The wet process starts by mixing polypropylene with a liquid. This mixture is spread on a surface and dried. Calendering makes the separator even. Tiny holes form so the separator can work with the battery’s electrolyte. The last step is finishing and checking quality.

The dry process uses powder mixed with other materials. This mixture is pressed into sheets and dried. The binder is removed. Sintering sticks the particles together. Tiny holes form with heat or chemicals. The last step is finishing and checking quality.

Polypropylene separators can handle high temperatures. They are lighter than other types. They also do not get damaged by chemicals.

Property | PP Separators | PE Separators |

|---|---|---|

Temperature Resistance | Handles heat better | Handles heat less well |

Density | Lighter | Heavier |

Melting Temperature | Melts at 165°C | Melts at 130°C |

Shutdown | Not listed | Shuts down quickly |

Tensile Strength | Not listed | Stronger |

Chemical Resistance | Resists chemicals better | Resists chemicals less |

Polyethylene separators help keep batteries safe. Polyethylene is a plastic used in batteries. It melts at a lower temperature than polypropylene. Polyethylene separators are in many new batteries. They can shut down fast if the battery gets too hot. This helps stop accidents.

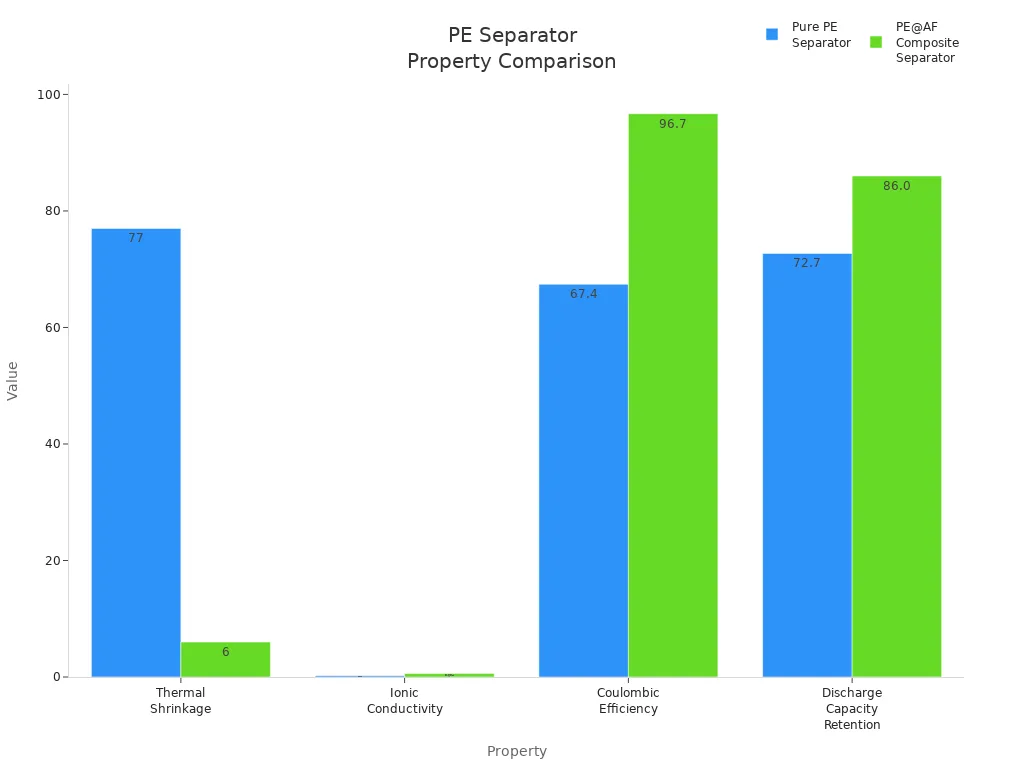

Polyethylene separators are heavier and stronger than polypropylene. They can shut down quickly if the battery overheats. This stops the battery from working. You can see how polyethylene separators work in the chart below:

Property | Pure PE Separator | PE@AF Composite Separator |

|---|---|---|

Thermal Shrinkage | Over 77% | 6% |

Ionic Conductivity | 0.206 mS cm−1 | 0.604 mS cm−1 |

Coulombic Efficiency | 67.4% | 96.7% |

Discharge Capacity Retention | 72.7% | 86.0% |

Special coatings can make polyethylene separators work even better.

You should look at the differences between polypropylene and polyethylene separators before you pick a battery.

If you look at battery separators, you should know how pp and pe are different. These materials have special features. They change how batteries work and how safe they are. Their chemical structure, strength, heat resistance, cost, and ways to change them make them unique.

A separator’s chemical structure affects how it works in a battery. Polyethylene (PE) and polypropylene (PP) are made from different building blocks. The table below shows how pp and pe are not the same:

Polymer Type | Monomer Composition | Molecular Structure Description |

|---|---|---|

Polyethylene | Ethylene | Long chains of carbon atoms with two hydrogen atoms attached to each carbon atom. |

Polypropylene | Propylene | Linear hydrocarbon polymer with a backbone of connected carbon atoms, with two hydrogen atoms attached to each side carbon atom. |

Polyethylene has a simple chain. Polypropylene has a backbone with side groups. This difference changes how each separator deals with heat and chemicals. Polypropylene resists chemicals better. Polyethylene shuts down fast when needed.

It is important to know how strong and heat-proof a separator is. The difference between pp and pe shows in their melting points and how they act with heat.

Polyethylene (PE) melts at about 135 °C

Polypropylene (PP) melts at around 165 °C

Multilayer polyolefin separators can shrink after thermal shutdown, especially the PP layer because it holds heat longer.

Polypropylene separators work well at high temperatures. You can use them in batteries that get hot. Polyethylene separators melt at lower temperatures. They shut down quickly if the battery gets too hot. This helps stop accidents. Multilayer separators let ions move better. They have more tiny holes and soak up more electrolyte. This helps batteries work better.

Evidence Type | Description |

|---|---|

Thermal Stability | PP/PE multilayer separators stay stable up to 160 °C and have a wider thermal shutdown range. |

Ionic Conductivity | Multilayer separators let ions move faster and help batteries work better. |

Manufacturing Process | Multilayer coextrusion makes it easier and cheaper to make separators. |

Think about the difference between pp and pe if you need a separator for tough jobs or lots of charging.

Cost is important when you pick a separator. The difference between pp and pe changes how much you spend and what you get.

Buying a strong PE separator may cost more at first, but it saves money later by cutting waste and warranty problems.

The separator you choose affects not just the price now but also how good and reliable your battery is.

A good PE separator keeps the production line safe and protects your brand, which helps avoid expensive recalls.

You can change both PP and PE separators for special batteries or industries. Companies use smart systems to change the tiny structure and how separators work. You can make separators that last in tough places and many charge cycles.

Aspect | Description |

|---|---|

Microscopic Structure | Changed to make batteries safer and work better for special uses. |

7-Dimensional Evaluation | A special system helps make separators for many needs. |

Performance Requirements | Made to last in hard conditions and many charge cycles. |

When you look at the difference between pp and pe, you see both can be changed to fit your battery. Pick the separator that matches your battery and your budget.

Polypropylene separators are used in many batteries. They are important in lithium-ion batteries. These separators stop short circuits. They help ions move better. Polypropylene helps batteries handle heat. You see these separators in lead-acid batteries. They are also in electric cars and portable devices. Polypropylene membranes are the top choice for battery separators. They help batteries work well in hot conditions. They keep batteries safe. Polypropylene separators are good for batteries that need to last long. They work well in hard places.

Battery Type | Why Use Polypropylene Separators? |

|---|---|

Lithium-ion | Stop short circuits, make batteries safer |

Lead-acid | Help batteries handle heat |

Electric vehicles | Help batteries work better |

Portable electronics | Make batteries more reliable |

Tip: Polypropylene separators help batteries stay safe when it gets hot.

Polyethylene separators help keep batteries safe too. You find polyethylene in new battery types. These separators melt at lower heat. This helps batteries shut down fast if they get too hot. Polyethylene separators are heavier and stronger than polypropylene. You see them in batteries for electronics, power tools, and energy storage. Polyethylene is good when you need quick shutdown and strong separators. Many companies add special coatings to make polyethylene separators work better.

Polyethylene separators keep batteries from getting too hot.

You use them in things that need fast safety.

Polyethylene helps batteries last through many charges.

There are some new trends in battery separators:

More people want electric cars. This means we need better lithium-ion batteries. So, we use more advanced separators.

Energy storage is growing as we use more renewable energy. Big systems need strong separators.

New technology brings new separator materials. Ceramic coatings and layers make batteries safer and better.

Note: You can pick separators that fit your battery and use the newest technology.

Polypropylene separators give batteries many good things. They can handle more heat because they melt at a high temperature. This keeps batteries safe when used a lot. Polypropylene is lighter, so batteries weigh less. It does not get damaged by chemicals easily. This helps it last longer in hard places. Polypropylene does not break easily under stress. This keeps the separator working well after many charges. Many companies use polypropylene because it is strong and costs less.

Polypropylene separators help batteries stay safe and work well when it gets hot.

Polyethylene separators are strong and shut down fast. They melt at a lower temperature. This lets them stop the battery quickly if it gets too hot. This keeps devices safe from accidents. Polyethylene is harder to stretch or tear. You see it in batteries that need to be tough. Polyethylene works well in batteries that get charged a lot. Companies add special coatings to make polyethylene more stable and better with liquids.

Feature | Polypropylene | Polyethylene |

|---|---|---|

Melting Point | Higher | Lower |

Tensile Strength | Lower | Higher |

Shutdown Capability | Slower | Faster |

Density | Lower | Higher |

It is important to know the problems before picking a separator. Polypropylene separators do not mix well with some electrolytes. This can make the battery work less well. They can shrink a little when very hot. This makes them less stable. Polypropylene does not stop lithium dendrites from growing. This causes uneven ions in the battery.

Polyethylene separators have their own problems. They have lots of tiny holes. This makes them easier to get damaged by chemicals. Polyethylene does not handle oxidation well. It can lose strength when stressed. Both types can have trouble with heat. This can make batteries less safe in very hot places.

Tip: Always pick the separator that fits your battery’s needs for the best results.

When you pick between PP and PE separators, you should think about a few important things. Each thing helps you choose the best separator for your battery. You want your battery to be safe, strong, and last a long time.

Factor | Description |

|---|---|

Safety | Safety is very important for electric cars and airplanes. You need separators that can handle high heat and are hard to poke through. This helps stop accidents. |

Pore size and porosity | Small pores let lithium ions move easily. Porosity shows how much liquid the separator can hold. It also affects how ions travel. You need to balance these for your battery. |

Thickness and mechanical strength | Thin separators help batteries store more energy. You need strong separators to keep the battery safe when pressed. |

Electrolyte compatibility | The separator must work well with the battery’s liquid. If they do not match, the battery might not work or lose power. You should know the chemical properties of both. |

You should also think about the environment. Many people want batteries that are good for nature. You can pick separators made from materials that can be recycled or are better for the planet. This helps cut down on waste and keeps Earth safe.

Tip: Always look at what your battery needs and make sure it is safe before you choose a separator.

PP and PE separators are not the same. PP gives batteries strong protection and lets you see through it. PE is bendy and can shut down fast. The separator you pick changes how safe, cheap, and good your battery is.

Choose a separator that fits your battery’s job and where it will be used.

Make sure the material works with your battery and is safe for the environment.

If you are not sure, ask someone who knows or talk to the company that makes batteries.

Separator Type | Best For | Key Benefit |

|---|---|---|

PP | High-heat applications | Strong protection |

PE | Fast shutdown needs | Flexibility & safety |

Picking the right separator helps your battery last longer and work better.

PP separators can handle more heat. They melt at 165°C. This keeps batteries safe when it gets hot.

Separator | Melting Point |

|---|---|

PP | 165°C |

PE | 135°C |

You can recycle PP and PE separators. Most recycling centers take these plastics. Always check your local rules before recycling.

Tip: Recycling helps the planet and cuts down on trash.

PE separators melt at a lower temperature. This lets them stop batteries quickly if they get too hot. Your device stays safer.

Pick PP separators for electric vehicles. They work well in high heat and last longer. This keeps batteries safe when used a lot.